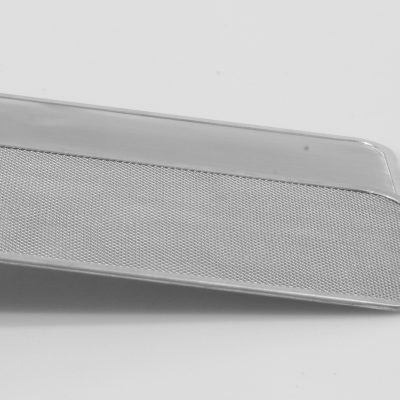

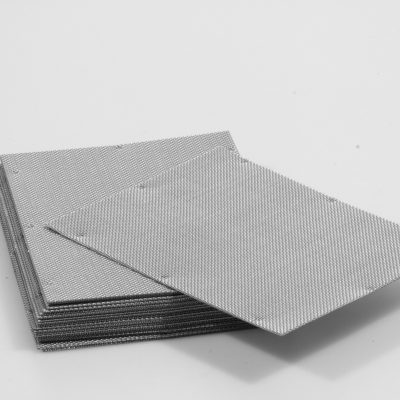

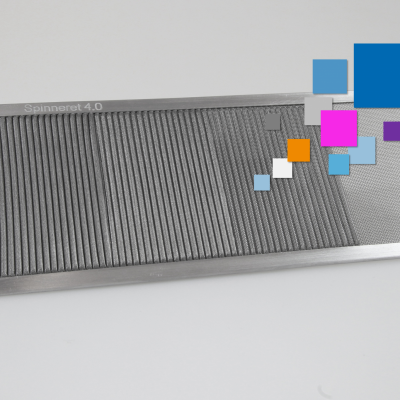

Precision long screens empower excellent product quality and long production uptime in plastic processes. Long screens are used to create filtration and dispersion in industrial processes. Their design and dimensions are defined based on the specific process and plastic used by a customer. We thereby realize solutions that allow each customer to exploit their true potential with regard to product quality and machine uptime. Accurate metal mesh cuts and product-specific sealings result in an ideal fit of a long screen in a production line. We manufacture longs screens according to your specific demands and also have standard dimensions and configurations available; i.e. for Reicofil nonwovens production lines.

Long screens

- Screens – ring

- Screens – kidney

- Insulation elements

- Filter belts

- Filter candles

- Cone filters

- Air rectifiers

- Air distributors

- Maxipass

- Pleated filter candles

- Precision elements

- Screens – round

- Regenerators

- Long screens

- Pipe sound absorbers

- Sieves

- Sieve baskets

- Cylindrical screens

- Custom shapes

- Filter rings

- Screens – framed

- Screens – oval

Details

Type: single-layer, multi-layer spot-welded, multi-layer framed

Dimensions: customer specific; length of up to 7m available

Material: aluminium frame; AISI 304, AISI 316, AISI 316L wire mesh; other specs. available

Fineness: 1µm – 500µm; fluid-specific design

Design: up to seven layers; material, fineness, structure customer-specific

INNOVATION

For nonwovens production lines we offer our latest long screen generation fteu® Spinneret Filter 4.0. Spinneret Filter 4.0 use and improved design and our fteu® MicroPleats with a height of 2.5mm to increase the efficiency of our customer’s processes. The design is exemplified on the photo above on the far right. An increased dirthold-capacity and optimized dispersion improve the product quality and reduce the need for spin pack maintenance significantly. Spinneret Filter 4.0 allow our customers to double their runtime without the need for a filter change.

Contact us regarding your demands and learn more about results as well as the potential of fteu® Spinneret Filter 4.0 for your processes.