For our customers we develop and manufacture functional solutions of metal mesh as well as metal fibres. We offer solutions for your machines and processes for the five functions Fluid Flow, Fluid Filtration, Heat Absorption, Sound Absorption and Engineered Precision.

Function in Permeable Metals

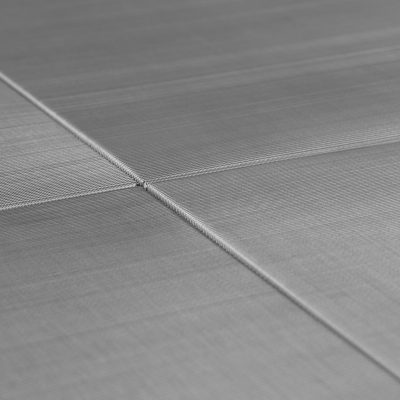

Fluid Flow

Optimized dispersion for your demands

Industrial processes are optimized and accelerated through the defined orientation of fluids – air, gas, liquid, melt. This function can be used to either avoid turbulence and gradients in flow speed or to create defined turbulence. The target-oriented application of fluid orientation allows the improvement of speed and availability of your processes. We realize improved orientation by addressing the three key functional parameters of fluid dispersion:

Flow orientation – Which fluid orientation should be created throughout the entire volume of the process space?

Fluid distribution – Which dispersion should be specifically created over the entire volume of the process space?

Efficiency – Which throughput – while allowing maximized production availability – should be achieved?

The fluid orientation and distribution are realized by using media with different structures and the specific combination of different structures. Thereby constant flow conditions are achieved or turbulences can be created in specific spots. Our metal mesh offer long lifetimes and are combined with other materials, i.e. honeycombs, to realize maximized efficiency of your processes with our products. Let’s talk about your demands!

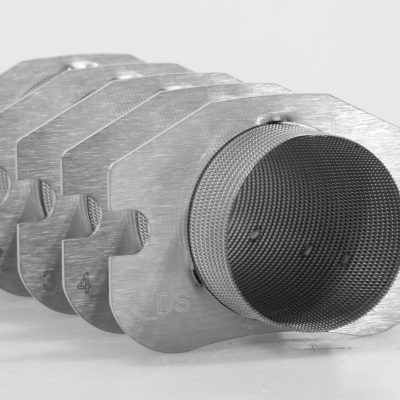

Fluid Filtration

Your filter according to your demands

Filtration is realized by filter elements that retain dirt particles and separate them from your process fluid. The filtration of fluid and gaseous materials enables efficient processes. The performance indicators process efficiency, process stability, and product quality are directly depended on your filtration. We increase the performance of your application through the optimization of the three functional key parameters of filtration:

Filtration fineness – Which particle sizes should be retained to achieve your target product quality?

Fluid flow – Which stream, dispersion, and pressure development should be achieved through filtration?

Efficiency – Which throughput – while allowing maximized production availability – should be achieved?

We optimize the value of the three functional key parameters in accordance with your specific demands. Our filter elements of metal mesh and metal fibres yield superior results specifically in conditions with high demands regarding pressure and temperature. The filtration fineness (1µm – 500µm) is engineered and specified using filtration media with various structures. The filter is designed to create an optimized fluid flow. Three-dimensional filtration surfaces yield maximum filtration efficiency even in small spaces using our fteu® MicroPleats. Let’s improve your filtration!

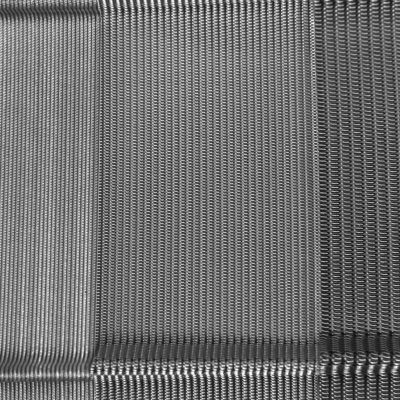

Heat Absorption

Porous absorbers for hot fluid processes

Porous temperature absorbers can precisely contain and process heat while at the same time a fluid can pass through the metal mesh structure. Heat absorption specifically for gaseous fluids can thereby be conducted in continuous processes. For the defined application of heat absorption three key functional parameters are relevant:

Heat diffusivity – Which reduction of temperature should be reached?

Openness – Which fluid stream has to be processed?

Efficiency – Which temperature absorption can be reached over time?

For heat absorption, we use metal mesh of different materials and density. With the customer-specific design we realize absorption solutions through a defined heat capacity and mass in a specific space. Additionally, we configure the openness through the selection and processing, i.e. compression, of specific metal mesh structures. In practice heat absorption is frequently used in combination with other functions such as filtration or sound absorption. What are your demands?

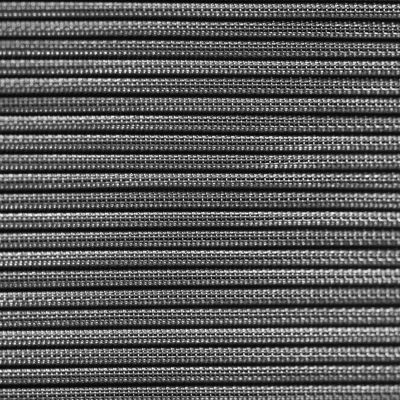

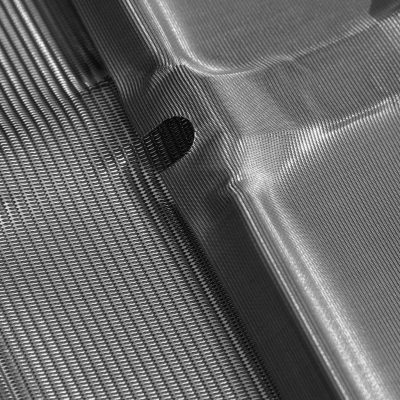

Sound Absorption

Fibre-free sound absorbers for your machines and equipment

Noise is reduced by the absorption of sound waves. This leads to improved conditions in and around your processes and machinery. The sound characteristics of your processes and machinery can be optimized through sound absorption. Better sound absorption means reduced and controlled noise emittance. We achieve better sound absorption by addressing the two key functional parameters of sound absorption for your application:

Sound reduction – Which absorption rate should be achieved for your application?

Efficiency – Which absorption rate can be achieved over time?

With our MASH® (Material Absorbing Sound and Heat) we reach high absorption rates – even for industry-typical low frequencies. At the same time, sound absorbers with MASH® achieve absorption fibre-free. Thereby fibres that were destroyed through sound penetration cannot affect the sound absorber. MASH® is a result of our product development, is manufactured on the basis of metal mesh structures, and can be shaped as well as specified with regard to its form and absorption characteristics for a wide field of applications. Let’s discuss your acoustics project!

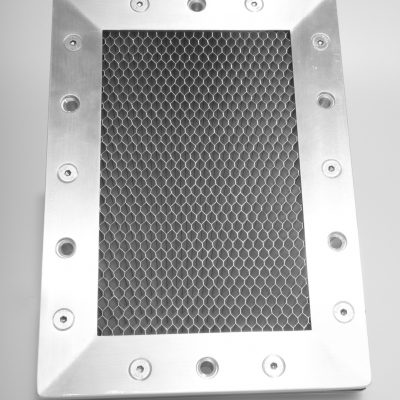

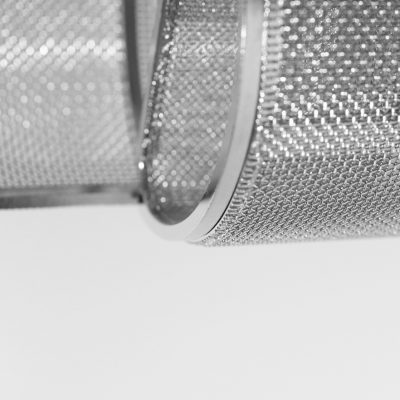

Engineered Precision

Precision assemblies of metal mesh

We create precision assemblies that meet the highest demands regarding manufacturing, haptics, and optics. Metal mesh offers unique structures and material characteristics that are ideal for i.e. for loading equipment or design elements. Our precision assemblies consist of different metal elements (metal mesh, sheet metal, laser-cut metal structures), that seek to address three key functional parameters:

Precision – Which accuracy and which manufacturing quality should be achieved?

Ergonomics – How has a precision element to be designed for our customer to be able to use it efficiently?

Efficiency – Which lifetime should our products achieve to ensure constant availability of our customer’s process?

With our technology in welding, our process competence for manufacturing metal mesh as well as our own tooling department we possess the relevant enablers for the design and production of precision assemblies. Our measuring stick are the highest demands with regard to design, handling, assembly, bonding spots, and surface quality. Thorough material selection and accurate production lead to precision assemblies that function consistently and are low-maintenance.